The most common and economic means of transporting goods are indeed the mighty ships sailing all across the vast seas spread across the world.

Ships are designed to carry a multitude of cargo like oil, grains, machinery, fruits, etc. and of course people. They move from port to port, loading and unloading at every halt.

By the Archimedes principle, we expect that, with every alteration in the weight of the contents of the ship, the effective weight changes, and that brings about a change in the draught.

Fluctuating draught lines may adversely affect the stability and manoeuvrability of the ship structures. And most importantly, we can never let the propeller, rudder and bulbous bow to rise above the surface.

Here comes the importance of ballast. Ballast by definition is any solid or liquid that is brought on board a vessel to increase the draught, change the trim, and regulate the stability or to maintain the stress load within acceptable limits.

With the introduction of steel-hulled vessels and pumping technology, the water became the perfect choice to be used as ballast, as it is easily pumped in and out of ballast tanks, possesses nearly no stability problems and is available all over.

The process of ballasting is basically loading water from one port and discharging it in the other as per the requirement. Even though the planet is blue all around, the water is not the same everywhere and so is the ecosystem.

So while ballasting a ship, the water is being taken from one ecosystem and mixed with some other. This intermixing of untreated ballast water has a lasting impact on the environment of the native area. Along with water, there are a plethora of aquatic species present, including all sorts of bacteria, microalgae, and various life stages of aquatic and plant and animal species. Species are considered alien if they are not native to a particular ecosystem.

Under optimum conditions, the alien species can survive and populate. Once they become dominant, the native species find it difficult to survive and may get extinct.

This breaks down the existing biodiversity of the place; impacts coastal industries, fisheries, and the local lives, be it economy or health. The treatment of ballast water is hence a necessary requirement in the efficient design of a ship, especially in the current era of green shipping.

Ballast Water Treatment

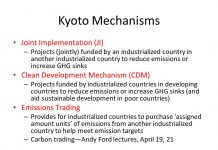

IMO’s “International Convention for the Control and Management of Ship’s Ballast Water and Sediments”, has made the implementation of ballast water treatment systems a priority.

A practical method to minimize the introduction of alien species from the ballast water discharge is Ballast Water Exchange.

The coastal water which can be fresh water or salt water is flushed out of the tanks with open ocean water, generally 200 Nautical miles away from the nearest land, at least having a depth of 200m.

It is expected that the temperature and the salinity differences would result in fewer chances of the survival of the added organisms. However, it has been determined that this method does not provide adequate measures to prevent damage taking place in the ballast vessel from the species.

Ballast Water Treatment Technologies

The technology for treating ballast water can be either port-based or ship-based, the latter being the more viable option.

Port-Based treatment:

This treatment requires that the ballast water be transferred to an offshore facility and then the necessary treatment is carried out. Valdez Marine Terminal, Alaska has one kind of ballast water treatment facility for decades to remove residual hydrocarbons from dirty ballast water.

Onboard treatment:

Currently, the on-board technologies available for ballast water treatment can be categorized based on their primary mechanism for inactivating the organisms; namely, Mechanical, Physical and Chemical.

Mechanical Systems

- Filtration:

Filtration is an effective method against sediments and various types of organisms. The physical separation can be done either during loading ballast or during the voyage. In this method, the particles are removed with disk and screen filters during ballast loading. These filtration systems can create pressure depressions and a decreased flow rate due to a resistance in the filter elements.

- Cyclonic Separation:

Cyclonic Separation is used for those particles with a specific gravity greater than that of water. The particles get separated from the water due to centrifugal forces. It is normally done using hydro-cyclones.

- Electro-Mechanical Separation:

A flocculent is added that attaches to organisms and sediments. They are magnetically separated and then filtered.

Physical Disinfection

- Ultraviolet Light:

UV systems are the most popular option at present. The UV radiation is used to attack the organisms outright or to destroy their ability to reproduce. The efficiency depends on the turbidity of the ballast water as this can limit the transmission of the UV radiation. The UV systems are suitable for any vessel but preferably for those who do not take in much ballast water and have flow rates of up to 1000 cubic metres per hour like RO-RO vessel, container ships, offshore supply vessels and ferries.