- Up to 90% reduction of NOx is achievable.

- 100% reduction in Sox emitted.

- Higher calorific value than fuel oil with about 20% reduction of CO2.

- Ease at storage and transportation.

- Highest safety records of any fossil fuel in past 40 years

BUNKER TANK ARRANGEMENT

Requirement for LNG tank –

- Flexibility in partial cargo loading

- Easy boil-off gas management (To cope with unfixed bunkering schedule)

- Low boil-off rate (To avoid loss of quality and amount of cargo)

- Low cost and low weight

Several Tank Options are available

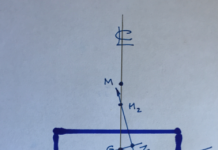

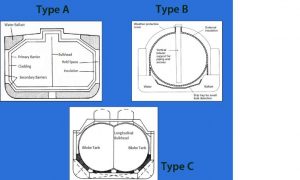

IMO Tank Types

- Type A & B are structural tanks built into hull

–low pressure requires constant consumption of boil-off gas (BOG).

- Type C cylindrical pressure tanks

–up to 10 bar pressure allows storage of BOG for up to two weeks.

Type C is most widely used for fuel tanks because they allow retention of BOG so there is little-wasted fuel.

Figure 1: Type C LNG fuel tank (New Technologies for the Marine Highway TRB -Marine Highways Committee (AW010 (1)) January 14, 2013)

For ocean-going vessels, large volume of LNG tanks to achieve desired range can eat up into the vessel cargo stowage. Tanks and tank compartment need special ventilation & tank vent piping to raised vent mast on deck. The need for special materials (stainless steel) for the cryogenic temperatures, need to be pressure vessels, and the need for gas control equipment make the fuel tanks expensive. LNG fuel containment safeties: Tank Room –space with equipment to gasify LNG located in vicinity of or attached to LNG Tanks. Double Wall Piping –recommend double wall piping. The space between the inner and outer pipes is vented to atmosphere. It allows LNG pipes to run through machinery spaces without creating hazardous areas. Redundant LNG Fuel Supply –recommend two supply pipes from Tanks to Engine for greater reliability. Gas Valve Units –self-contained units, one for each engine, fitted in engine room -contain gas flow control and shut down equipment Vent Riser Mast –height is Beam/3 above weather deck, hazardous outlet.

Bunkering requirements:

Issues to be addressed

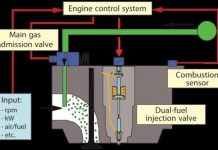

- Propulsion system for LNG fuel

- LNG fuel tank(s)

- System for supplying LNG fuel to engine(s) and handling boil-off gas

- LNG fuel bunkering system

- Sufficient LNG fuel supply chain

Ideas for bunkering LNG fuel;

- Via LNG fuel bunker station (Similar way for LNG carriers)

- Via LNG tanker lorries (Currently popular way in North Europe)

- Via LNG fuel bunkering ship (Ship-to-ship)

LNG fuel use and bunkering require special crew training. LNG bunkering interface with LNG receiving ships 1. by loading arms 2. by flexible hose

Ideas for LNG bunkering interface with LNG receiving ships

- Similar concept to LNG terminals, but specialized modification for ship-to-ship use is necessary.

- Some actual cases already done by Ship-to-Ship using flexible hose. This is the most feasible way at this time.

Conclusion: Use of LNG as ship fuel is going to increase in future, once the world supply chain for LNG becomes strong all over the world. Bunkering, storing and using of BOG in GI engines all have its own challenges. But proper training of crew and better technological advancements has made it a reality. LNG is a far cleaner fuel, and so the environmental benefits obtained would be substantial.