The global shipping industry has put a step forward by rejuvenating itself to the digital shipping. The Shipping Container IoT visionary Loginno is initialising an all-star initiative to select one shipping company, whose entire container fleet will be digitalized in 2019.

From the last 6 months, the shipping companies of mid to small size were given a chance to submit an executive summary, detailing what they can do exactly if they are selected to equip their entire fleet with Loginno’s patented tracking and monitoring devices. A panel of industry leaders will then decide who will be the lucky winner to be propelled to the forefront of marine innovation.

The global shipping industry is counting on June 6th disclosure for the first ever digital shipping company, IoT visionary Loginno announces Contopia’s pioneering core technology.

The initiative “The Contopia Factor,” comes up from the word Contopia (a mesh of “Container” and “Utopia”), is a term used to describe a world where every shipping container is real-time IoT linked.

Shipping organizations witnesses’ intense pressure to function more efficiently and profitably while catering to the progressively sophisticated, digital demands of their customers. Ongoing overcapacity, mated with a relatively soft global demand, is putting massive pressure on the rates and profit margins of shipping companies.

Meanwhile, the customers themselves are buzzing for faster and more streamlined services that afford integrated service. The end-to-end logistics capabilities versus port-to-port offerings. Even the most trustworthy customers are now moving to providers who offer solutions outlined to deliver deeper value along the supply chain.

Digital transformation offers a way to get there, and sophisticated shipping competitors are well aware of the same. Innovative players are quickly bypassing traditional shippers with advanced and efficient digital business platforms that deliver more benefits to customers. Digitalization isn’t just a nice-to-have philosophy. It’s the very key to survival, and aids as the launch point for transformational turnaround.

WHAT DIGITAL SHIPPING CAN DO –

The master-plan for success draws upon three digital aspects – develop new business models and offerings, digitalize core operations, and build a strong internal digital foundation. For shipping organizations, the transformation model demands the following:

- DEVELOP NEW BUSINESS MODELS AND OFFERINGS

- DIGITALIZE THE CORE BUSINESS

- BUILD A ROBUST INTERNAL DIGITAL FOUNDATION

- DEVELOP NEW BUSINESS MODELS AND OFFERINGS

- Easy online booking platform. “One-click” online booking has become a must to stay relaxed. It allows shipping companies to strengthen the direct relationship with their consumers and win new ones, attracted by the clarity of booking online.

- High-Margin Services. The E-commerce platforms and advanced cargo management systems grant liners to extend their offerings into higher-margin fields of the supply chain, like intermodal and warehousing solutions.

- Next-Generation Solutions. Real-time cargo tracking and onboard sensors that monitor cargo conditions attend customer demands for better visibility all over the shipping journey.

- DIGITALIZE THE CORE BUSINESS

- Revenue Management. Robust analytics decipher dynamic pricing and contract portfolio optimization with compelling revenue-enhancement opportunities.

- Advanced Analytics on System Costs. Advanced modeling allows optimization in network design, vessel deployment, cargo routing, and blank repositioning to lessen costs.

- Blockchain Technology. An Opportunity for the industry to streamline and secure the documentation process.

- Digital Lead Management. Connected market intelligence and lead management amidst liners to leverage the broad network of agencies and significantly raise customer bases.

- Enterprise Resource Planning (ERP) Interfacing. Linking ERP functionality between liners and customers allows advanced capacity planning and bolsters customer lock-in by supplying an automated booking system precisely from customers’ own ERP systems.

- Control Tower Fleet Monitoring. Tracking fleet activity, by leveraging millions of data and onboard sensors, grants continuous routing and vessel performance optimization onward with predictive maintenance.

- Multi-Modal Collaboration Platform. Exchanging information between liners, terminals, and intermodal companies can enhance the efficiency of port call and connection with intermodal.

- BUILD A ROBUST INTERNAL DIGITAL FOUNDATION

- Talent. Implementing—and publicizing—a strong digital foundation across the organization aids to attract the right digital talent in shipping to help keep the business increasing and running more productively.

- Systems. Modernizing systems to take benefit of advanced data and predictive analytics empowers growth-minded intelligence and decision-making facilities.

- Agility. Instilling a way of working during the whole of the shipping enterprise that allows shorter innovation cycles to further quickly develop solutions.

- Digital Organization. When companies incubate new digital offerings, they can sometimes get advantages from developing a new organization that is independent of the core.

PERKS OF DIGITAL SHIPPING

- Time-saving

- Cost reduction

- Greater efficiency

- Cleaner transport

- Higher customer satisfaction

- Operational stability

- Security and error prevention

WHERE DO WE STAND – DIGITAL SHIPPING

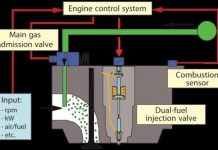

Connectivity: Connectivity in shipping industry proposes many advantages such as remote asset management that leverages data from critical on-board equipment systems to allow more efficient maintenance through predictive diagnostics. It further aids in vessel operations optimization as well as in route management for improved fuel efficiency, while smart sensor and actuator networks help enable safer ship operations.

Electronification:

The electronification benefits in shipping industry can be divided in three areas;

- The electronic exchange of information on cargo, crew but also passengers with the aim to reduce errors, improve tracking and traceability, and reduce freight waiting and stopover times.

- The electronic ship clearance: The FAL Convention was agreed amended to require the implementation of electronic ship clearance by April 2019. This decision was also followed by information that IMO is continuing its work on developing a prototype electronic single window software for interested member states. Electronic and digital port clearance will simplify the port call process, but it will also force the administrations to go through all their reporting requirements and hopefully reduce the confusion related to what information is required in what format in what port.

- The support of electronic ship certificates: Many flag states now offer the opportunity of electronic ship certificates, as PDF documents that can be printed out when needed. Such certificates can be developed as fully electronic documents, e.g. in XML format, with secure digital signatures.

Machine learning: As of now in shipping industry we see machine learning techniques, in the area of performance assessment, fault diagnosis, predictive diagnosis and optimization in service.

Internet of Things: Thanks to IoT cargo handling and pre-emptive maintenance are becoming easier. This technology can improve the cargo handling based on satellite coverage, common sensor technology and the power of cloud computing, collecting data including voyage, weather, maintenance, machinery and state of cargo.

However, although shipping industry seems to embrace digital transformation, falls short in the transformation of business by changing the business strategy.

Conclusion

Water transport constitutes 80% of world trade movement. Shipping has undergone a massive transformation since the 1980s. With the development of shipping fleet and technologies, there has been an overcapacity leading to a fierce competition among shipowners to carry the maximum volume.

The Shipowners face various regulatory pressures from IMO and international trade policies of various governments affect the trade and hence profit margins. With the above boundaries, a shipowner is left with very few choices to enhance his profit margins.

OPEX comprises nearly 20% of paperwork/planning/tracking/warehouse management etc which is a considerable amount. This area is now seen as an improvement potential to reduce the time factor and operating cost. Same demands for an integrated service to efficiently manage resources and the chain flow. Digital shipping is the answer, it will be a platform where things will be simplified for an end user. It will be a drive to generate volume and improve the economy.